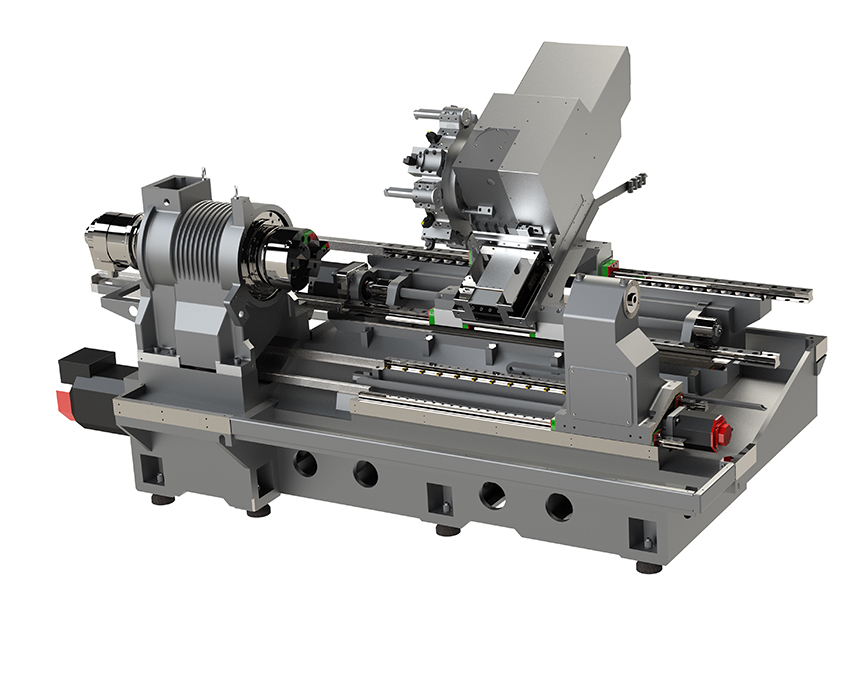

1.FEA technology is used to analyze complex working conditions, simulate and analysis changes under various working conditions; The complexity and high rigidity design, optimize the structure, and ensure the excellent performance of the machine.

2.Step type headstock structure, large span and strong rigidity, especially suitable for heavy cutting.

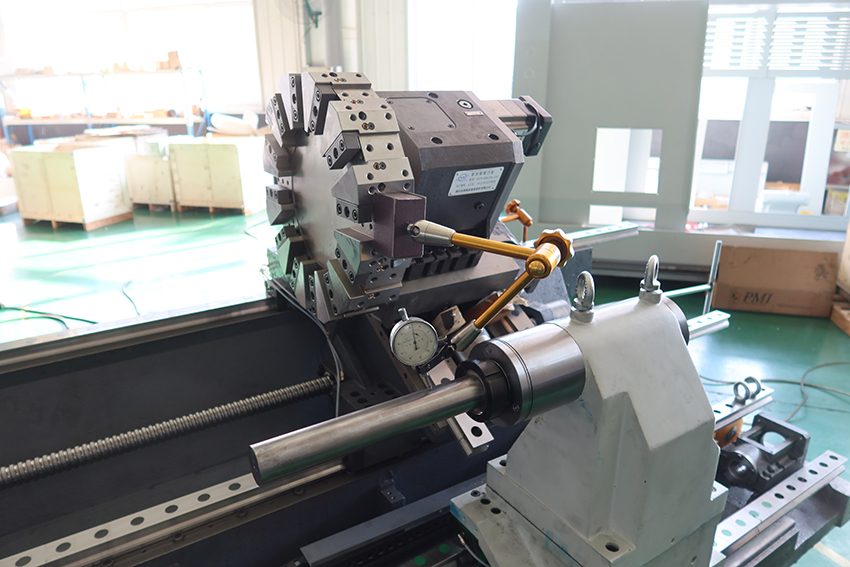

3.Advanced integral spindle structure, improve assembly accuracy, contribute to high-precision cutting.

4.Roller bearings of type NN assist in heavy cutting, angular contact ball bearings absorb axial cutting forces.

5.High rigidity step guideways, 30° integral slant bed, increasing the bottom area, improving the rigidity of the bed, and helping to heavy cutting;

6.The X-axis adopts rectangular box way to improve vibration damping and dynamic rigidity, for heavy-duty cutting.

7.The Z-axis uses 55mm linear roller guideway, high rigidity, high speed and high accuracy.

8.Standard hydraulic programmable tailstock, optional servo programmable tailstock.

9.Optional: Sub-spindle; Chip conveyor; Hydraulic steady rest; Bar feeder; Oil mist collector; Safety door lock, etc.