Features:

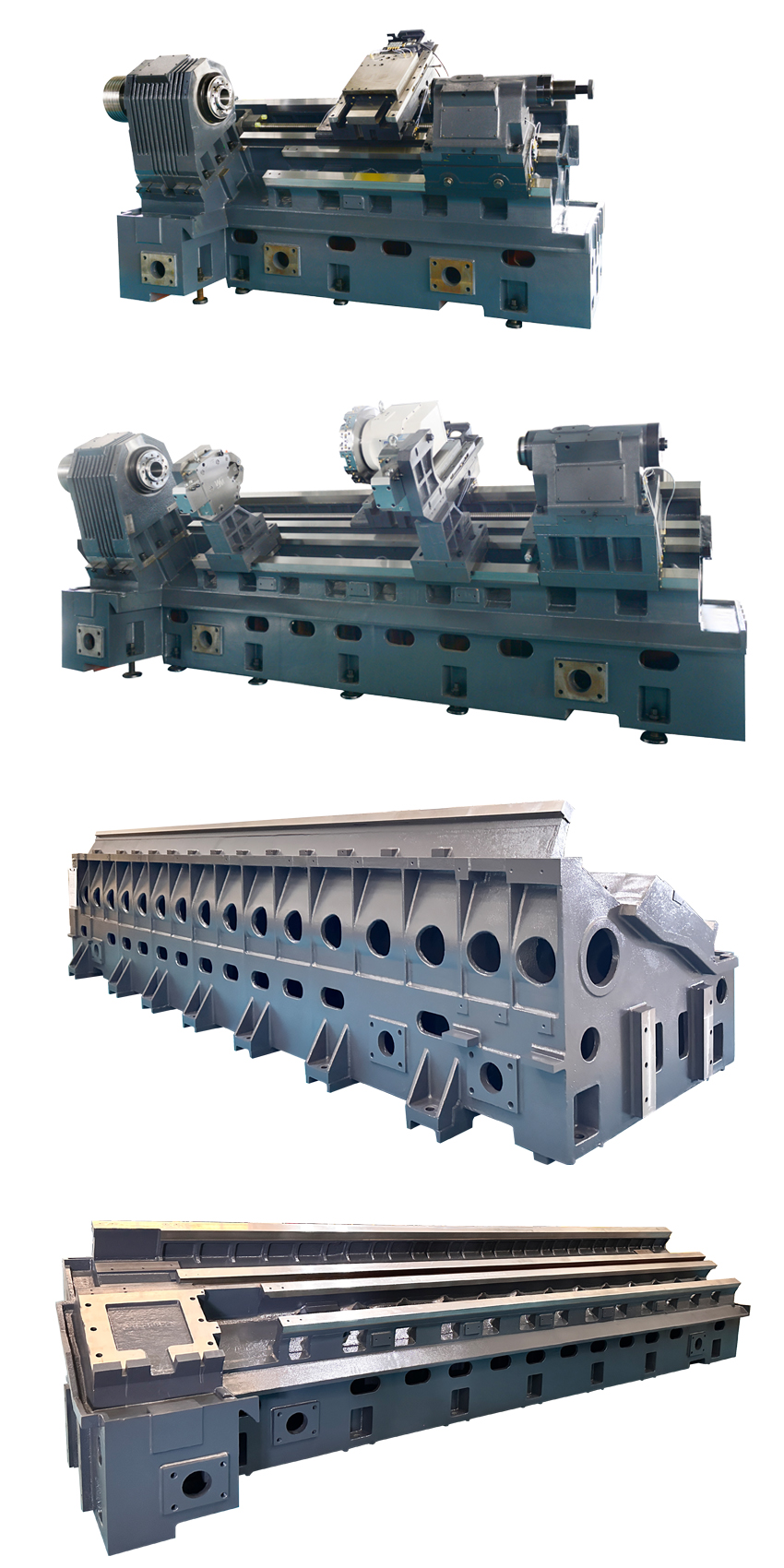

1. Optimized main unit structure via FEA reduces machine height while maintaining dynamic rigidity under heavy cutting.

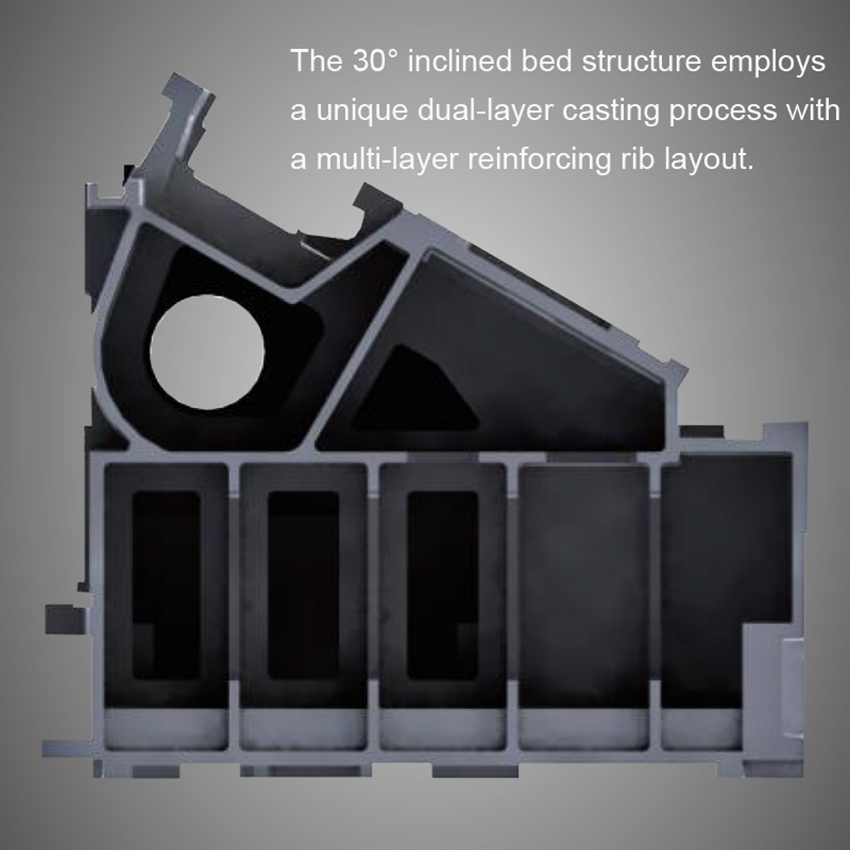

2. Integral 30° slant bed made of high-strength HT300 cast iron. High-rigidity stepped box ways undergo precision grinding in single clamping; slideways feature wear-resistant inserts with hand-scraped precision mating. Bearing/motor housings use embedded scraped assembly, significantly improving stability and accuracy retention during heavy cutting.

3. The spindle employs a low-speed high-torque motor with a two-speed automatic hydraulic shifting mechanism. 1:2.5/1:7.4 reduction ratios enhance low-speed torque, enabling both rigid and high-speed cutting. X/Z axes utilize high-power servo motors ensuring rapid response. Eight Japanese industrial-grade multi-groove belts increase contact area and friction with pulleys for stable high-speed operation.

4. Independent integrated cutting fluid tank: The cooling fluid tank is installed at the front of the machine bed to prevent leakage, and maintains stable machining by using high-power cooling fluid.

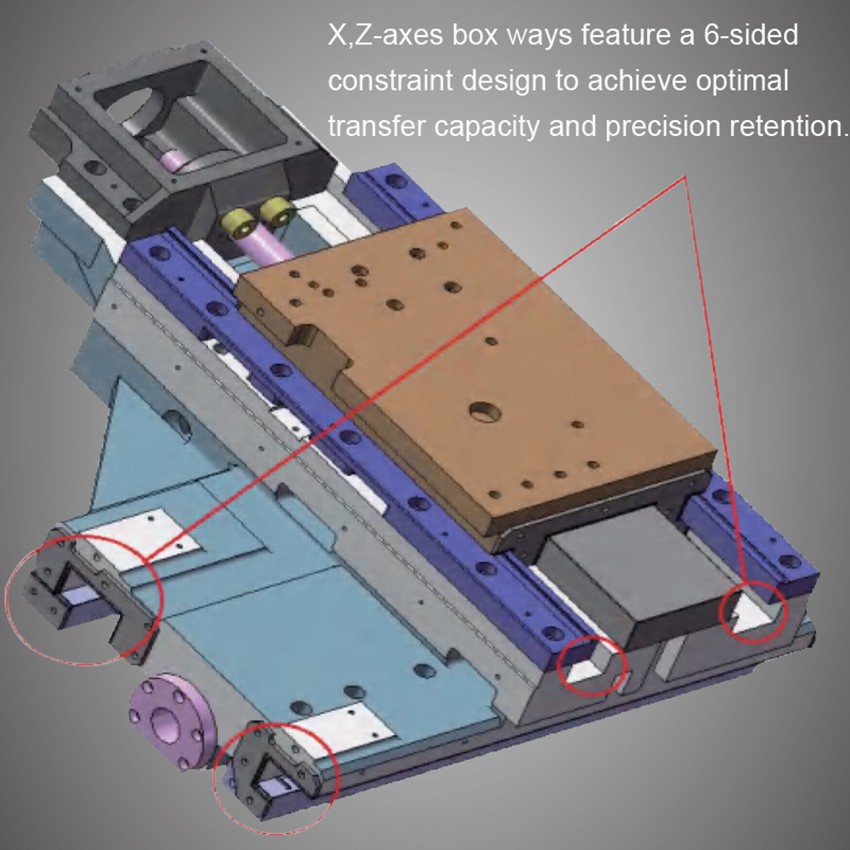

5. The X,Z-axes adopt a box-type guideway design, featuring better mobility. The box-type guideways have a strong ability to counteract vibrations caused by cutting, reducing tool wear and improving machining stability. In particular, the X-axis is designed with a sealed built-in structure, which can minimize damage to the turret from chips.

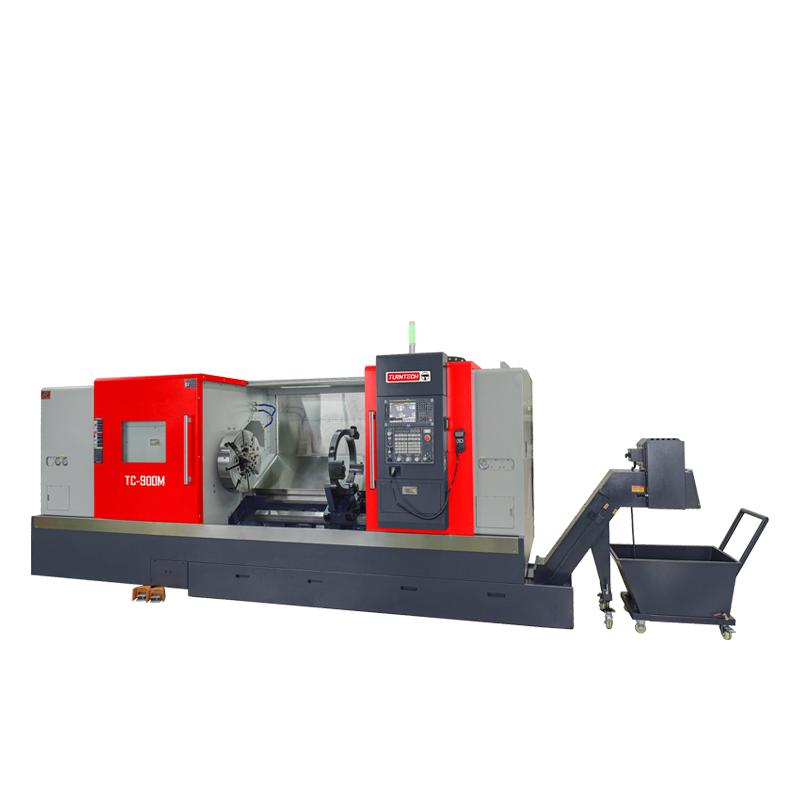

6. The TC-900 comes standard with a servo turret.

The TC-900M comes standard with a power turret. It features the fast and precise tool changing performance of a servo turret, combined with power milling via a high-speed power spindle, achieving excellent turn-mill composite machining capability.

The TC-900MY comes standard with a power turret, adopting a orthogonal Y-axis design. The box-in-box center-of-gravity driving structure is integrated with the turret, ensuring balanced force during machining.

7. Standard MT.5 (Opt: MT.6, ∅150/150mm sleeve diameter/stroke) hydraulic programmable tailstock. Optional servo programmable tailstock.

8. Options: Hydraulic steady rest; The electric spindle and dual spindles; The spindle gear box.