1.Jointly designed in Switzerland and Japan, produced by Chinese OEM.

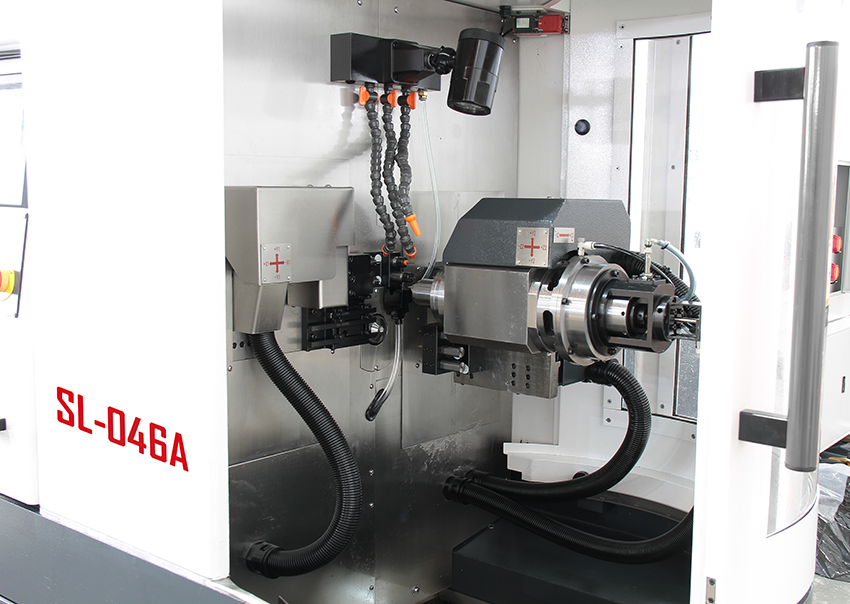

2.Integrated machine base to ensure rigidity and stability.

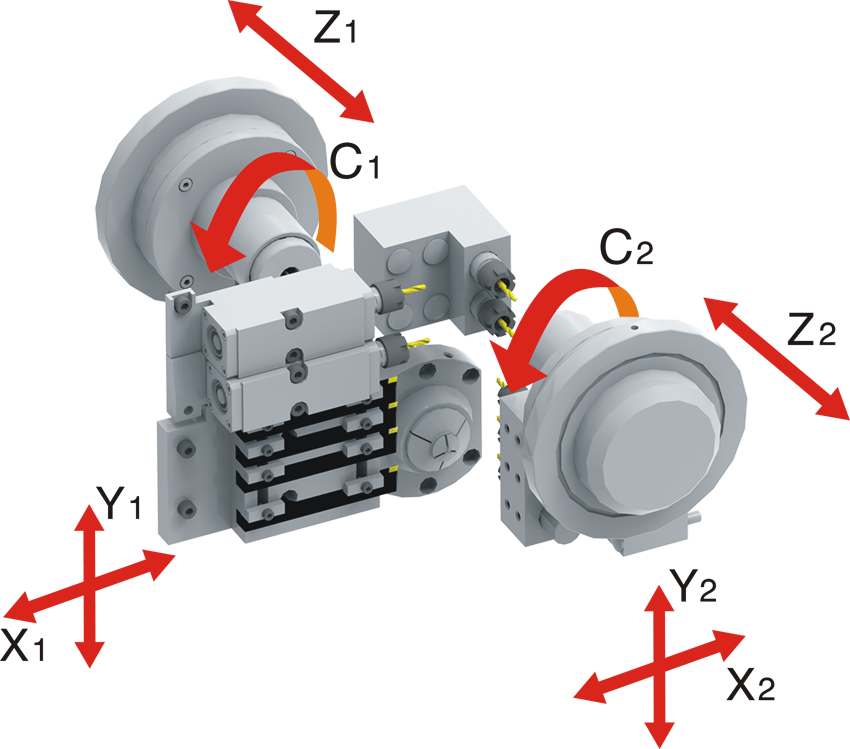

3.Built in spindle motor for both main/sub spindle. High precision ball bearing. CS axis control and indexing.

4.Compact structure with low vibration and noise.

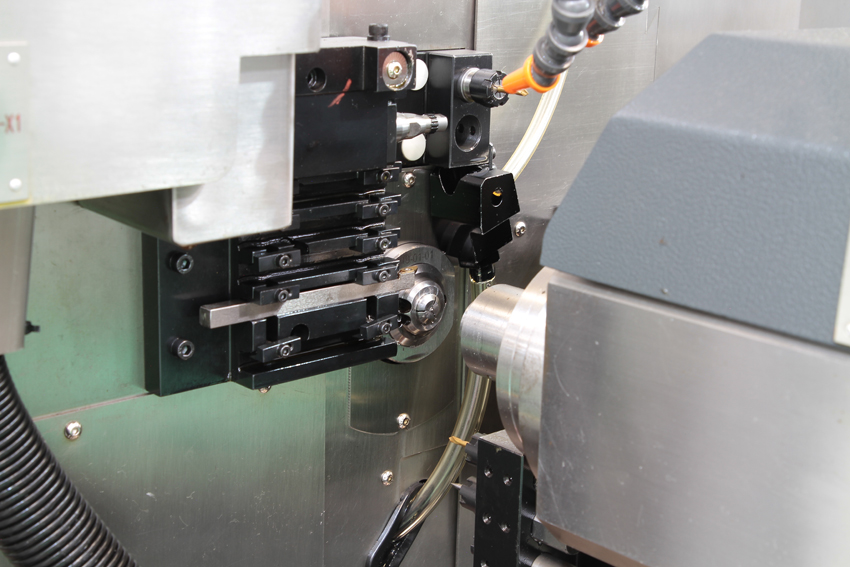

5.Gang tool slide with movable headstock. Full stroke rotary guide-bush for supporting during cutting.

6.AC servo control for X1, X2, Z1, Z2, Y1, Y2 axes. 4 axes could be simultaneously controlled. Built-in absolute encoder. High precision linear guideway and ball screw, high positioning accuracy and rapid travel speed.

7.FANUC 0i-TF Plus dual port control system with LCD display and MPG control. Self-diagnosis is available.

8.Full closed cover with tempered glass observing window for machining zone.

9.Emergency stop button to stop the machine whenever necessary.

10.Inter-lock device for spindle and spindle collet.

11.Override protection for X1, Y1, Z1, X2, Z2 slide and overload protection for X1, Y1, Z1, X2, Z2 servo motor and cooling motor.

12.After connecting with the bar feeder, automatic feeding of multi-bar material can be realized.