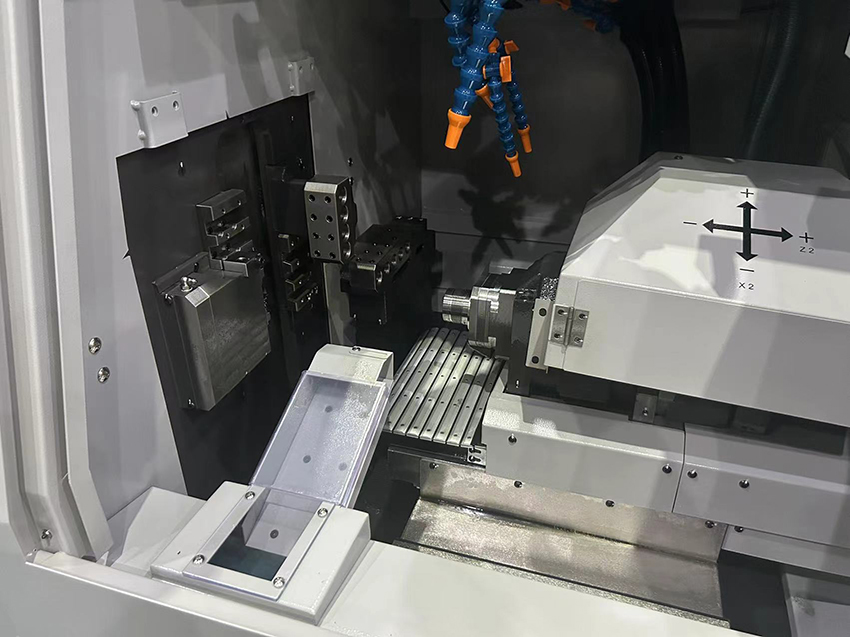

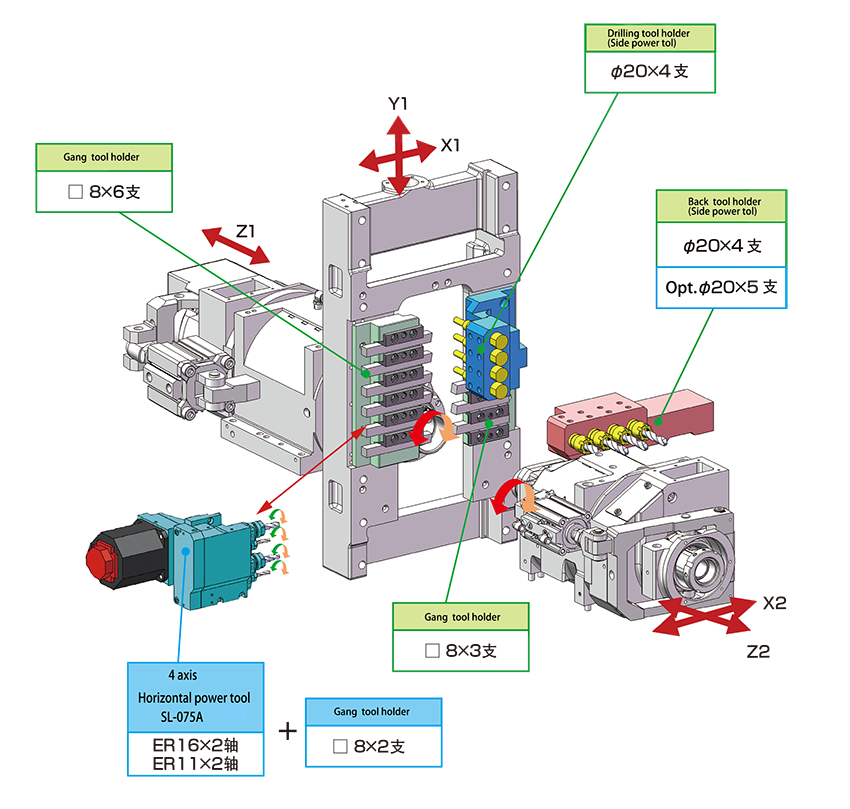

1.SL-075A is a compound CNC precision machining automatic lathe with double-spindle, double-system, double -toolholder and 5-axis control.

2.Super Cost-effective model.

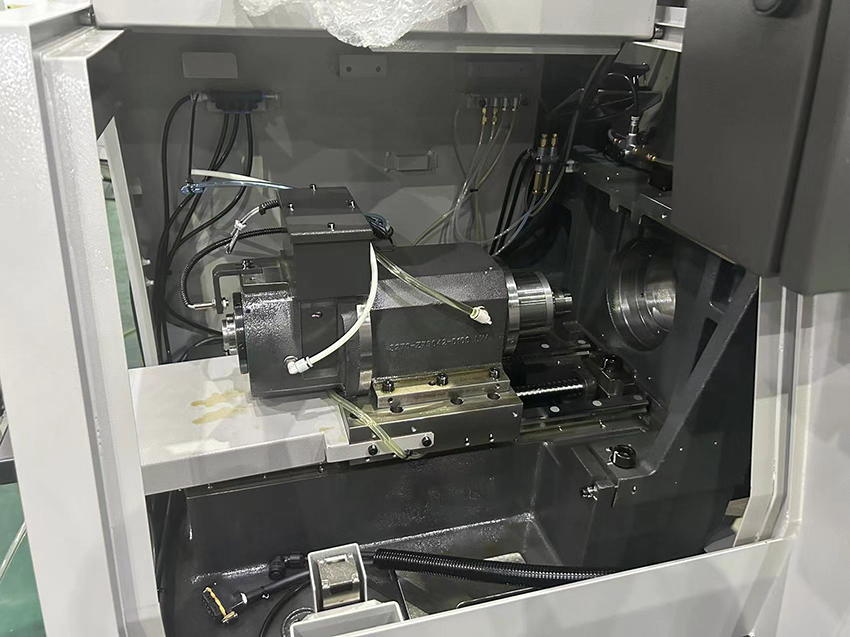

3.The toggle is replaced with Japan’s unique chuck mechanism which provides the quick response and better balance characteristics. Contributes to finer roundness at high speed rotation.

4.Ceramic ball bearings are mounted on the main spindle which enables a stable turning pattern, improves surface roughness, and prolongs tool life.

5.Opposed gang tool post to reduce the movement distance and achieve the shortest indexing time.

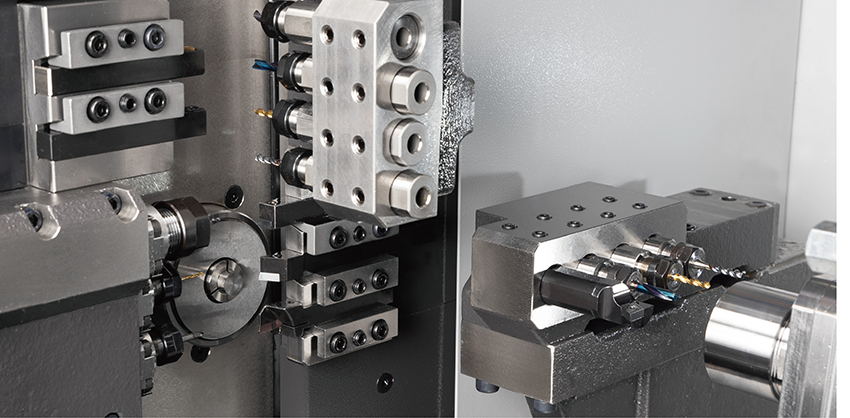

6.It is used for the processing of various composite parts. Materials are mainly stainless steel and non-ferrous metals. The equipment can complete the turning, milling, drilling, tapping, threading, and grooving processes in one clamp. With the back processing ability and lateral processing ability.